- HOME

- About us

-

Product

ProductDetailSimple substanceTellurideSputtering targetiodidefluoridephosphidesulfidechlorideCutting-edge materialsselenidebromideoxide

-

Molybdenum telluride

Molybdenum telluride

-

Tin telluride

Tin telluride

-

Silver telluride

Silver telluride

-

Tellurium antimony germanium

Tellurium antimony germanium

-

cuprous telluride

cuprous telluride

-

Bismuth telluride

Bismuth telluride

-

Cadmium telluride

Cadmium telluride

-

Gallium Telluride

Gallium Telluride

-

Aluminum iodide(AlI3)

Aluminum iodide(AlI3)

-

STRONTIUM IODIDE

STRONTIUM IODIDE

-

Hafnium(IV) iodide

Hafnium(IV) iodide

-

Tetra Tin(IV) iodide

Tetra Tin(IV) iodide

-

Chromium triiodide

Chromium triiodide

-

Lead iodide

Lead iodide

-

Cesium Iodide

Cesium Iodide

-

Cuprous iodide

Cuprous iodide

-

Barium Fluoride

Barium Fluoride

-

Aluminum fluoride

Aluminum fluoride

-

Magnesium fluoride

Magnesium fluoride

-

Cerium fluoride

Cerium fluoride

-

Ytterbium fluoride

Ytterbium fluoride

-

Indium trifluoride

Indium trifluoride

-

Hafnium disulfide

Hafnium disulfide

-

Antimony Trisulfide

Antimony Trisulfide

-

Tin monosulfide

Tin monosulfide

-

Germanium monosulfide

Germanium monosulfide

-

Zirconium sulfide

Zirconium sulfide

-

Cobalt disulfide

Cobalt disulfide

-

Silicon disulfide

Silicon disulfide

-

molybdenum disulfide

molybdenum disulfide

-

Chromium(II) Chloride

Chromium(II) Chloride

-

Bismuth Chloride

Bismuth Chloride

-

Palladium Chloride

Palladium Chloride

-

Ruthenium chloride

Ruthenium chloride

-

Ferric trichloride

Ferric trichloride

-

Tellurium tetrachloride

Tellurium tetrachloride

-

Hafnium tetrachloride

Hafnium tetrachloride

-

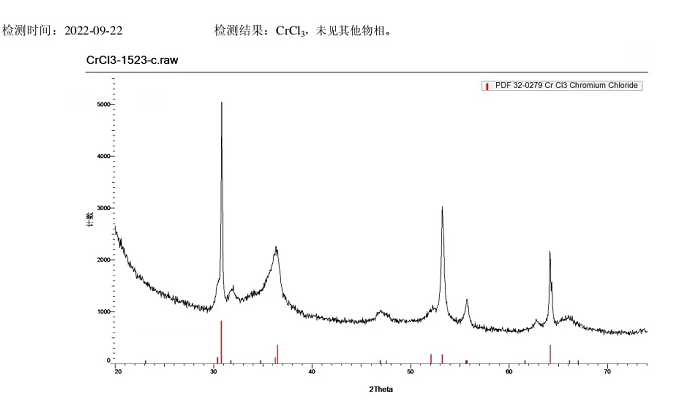

Chromium trichloride

Chromium trichloride

-

Cadmium arsenide

Cadmium arsenide

-

Hydrated Indium(III) nitrate

Hydrated Indium(III) nitrate

-

Gallium nitride powder, target material

Gallium nitride powder, target material

-

Indium acetate

Indium acetate

-

Tellurium cadmium zinc

Tellurium cadmium zinc

-

CIGS

CIGS

-

Copper zinc tin sulfur

Copper zinc tin sulfur

-

Cadmium stannate

Cadmium stannate

-

Molybdenum diselenide

Molybdenum diselenide

-

Titanium selenide

Titanium selenide

-

tungsten diselenide

tungsten diselenide

-

Gallium trislenide

Gallium trislenide

-

Antimony triselenide

Antimony triselenide

-

indium selenide

indium selenide

-

bismuth selenide

bismuth selenide

-

CdSe

CdSe

-

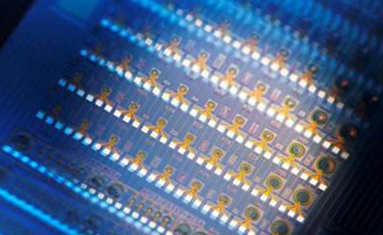

- Process Route

-

Technological Innovation

Technological InnovationDetail

-

Partners

PartnersDetail

-

Cooperation Case

Cooperation CaseDetail

- CONTACT US